BURLINGTON MOM, DAUGHTER SHINE

Methodists’ Sewing Club

Making Scarce Face Masks

By LIBBY CUDMORE • Special to www.AllOTSEGO.com

BURLINGTON FLATS – The sewing that Michealle Cole, a Cooperstown Central second-grade teacher, uses as her “therapy” will help protect healthcare workers from COVID-19.

“All I want to do is put a smile on people’s face,” she said. “Sewing is my therapy.”

Cole, part of the Fly Creek United Methodist quilting group, has made more than 75 face masks to be donated to Bassett Hospital as shortages of protective gear loom.

“We became aware there was a need at Bassett Hospital for masks,” said Rev. Sharon Rankins-Burd. “Someone found a pattern online, and apparently a lot of people are making these.”

While the masks are not full protection against COVID-19, she said, they will help health-care workers at Bassett reduce the risk.

“While fabric masks are not a substitute for health-care-grade respirator-type masks, this is a coordinated effort to use the fabric masks to extend the life and supply of the respirator masks,” said Bassett pharmacy director Kelly Rudd. “These respirator masks are in critical short supply nationally, and provide the best protection for our health care workers, patients and community.”

Rudd says the handmade fabric masks will be disinfected can be used repeatedly throughout the coronavirus threat, according to guidance provided by the Centers for Disease Control and Prevention (CDC) for the use of fabric masks during a crisis response.

“They’re reusable, you can wash and dry them,” said Cole.

For those who can’t sew, there are still ways to assist, including donating supplies or money to buy supplies. In all, Bassett believes they will need 20,000 masks.

The pattern calls for two rectangles, 9 by 10 inches, of “tightly woven” pre-shrunk cotton fabric – no red, as it might run when laundered – and one of batting – either flannel or thin quilt batting – and two elastic loops to go over the ears. One yard of fabric can make approximately five masks.

“You can even use hair ties for the elastic,” said Rankins-Burd. “And since it’s not like we can just run to the fabric store, you can use up what you have.”

“All my fabric was leftover from quilts,” said Cole. “I could take all those little pieces and put them together. It only takes about 10 minutes.”

Rankins-Burd shared the pattern with the weekly quilt group, as well as with other churches. “People are excited,” she said. “It’s a way to keep busy when you’re stuck indoors.”

For those who want to join the effort to make fabric masks, the Fly Creek Methodist Church will serve as a drop-off point for anyone interested in making the masks, which will be taken to Bassett Hospital for distribution. Masks may also be dropped off at Bassett’s warehouse, 26 Grove St. in Cooperstown.

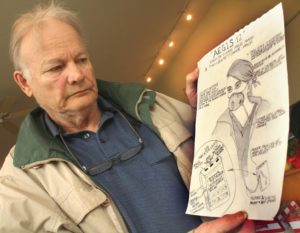

Similarly, local inventor Gerry Welch believes he may have an answer to the face-mask shortage the nation is facing.

For several years now, Welch has been promoting the “Aegis 12,” which the publicity describes as a “Healthcare Face Mask with Fail-Safe Power Pack.”

The device is two face masks with a silver foil layer in between, attached to a power pack that may be placed in a breast pocket or hung around the user’s neck.

The power pack, connected to the mask with a fiber-optic cable, provides “a high-intensity shortwave UV” that disinfects the air drawn into the center chamber through a louver in the front mask.

Welch, whose inventions include the Skeeter-Eater, a non-toxic means of reducing the mosquito population, said the Army has a 2010 patent on a similar device, but the energy source is in the mask itself, which soon heats up uncomfortably.

Regardless, the Army’s patent suggests the concept has merit.

He is seeking a patent on the mask with the assistance of Jay Yablon, the Schenectady lawyer who obtained the Skeeter-Eater patent, and meanwhile has contacted Corning, which manufacture fiber-optic cable, to gauge its interest.

And Ivan Potocnik, an Oneonta native now living in Utica, has joined with a network of 3D printer enthusiasts in making shields for medical visors. “My friend Toni DiPalma in Albany reached out to a network of friends with 3D printers,” he said. “It’s modeled on a Ukrainian design, then finished and put all together with sheet plastic.”

The shields take three hours each to print, but Potocnik believes that, working together, the network can produce as many as 20 a day.

“We’re all trying to contribute any way we can,” he said. “And we hope we can inspire other DIY-ers to do the same.”

“If you can make two or 20 masks, it will help,” said Rankins-Burd. “It’s a good, positive thing to do when you feel helpless.”

Hi everyone,

This is Ivan Potocnik, and I just wanted to let you know that we’ve had great success so far with printing our PPE medical visors and distributing them around various communities. We’ve also refined our method/design allowing us to print one of these shields in just over an hour (down from 1 every 3 hours). If you have any interest whatsoever in following what we’re up to or lending a helping hand by donating to our GoFundMe page, it would really go a long way in helping to get these medical visors into the hands of this pandemic’s front-line responders that desperately need them. We’re totally committed to charging zero dollars and zero cents for these masks, so any donations from you go 100% directly to the cost of materials. Thanks so much for hearing me out and I hope everyone is staying safe and healthy out there.

LINK TO FACEBOOK PAGE: https://www.facebook.com/RIST3DPrinting

LINK TO GOFUNDME: https://www.gofundme.com/f/3d-printing-medical-shields-for-medical-workers?utm_source=facebook&utm_medium=social&utm_campaign=p_cp%20share-sheet&fbclid=IwAR2MdRIG8j4ldh1Ohu0kjAvXNX4Qz2ryqueJZ3m6dlzvMkYpEURjt_EwNvs